:: Cuplock System ::

Cuplock / Cup lock is a unique node point connection allows up to four horizontal members to be connected to a veritical members in one single action – without the use of nuts and bolts or wedges. The locking device is formed by two cups. Single node point action of unique locking make ‘cuplock/Cuplock‘ a fast, versatile and optimized system of scaffolding for scaffolding for construction, demolition and maintenance projects throughout the globe.

Silent Features:

Various Cuplock Systems manufactured by CHAUDHARYSCAFF are as follows :

|

TOP |

|

| Transoms are fabricated from twin structural angles fixed back to back with a drop forged blade attached to each end. The 1.8m and above Transom has an additional web member welded below the flange section for added strength. The transom blade locates into a bottom cup and is locked in position by the top cup. The outward standing bottom leg of the angles supports the steel planks in a captive manner. Available in various lengths to suit scaffolding and formwork applications. TOP |

| Omega Transoms manufactured from press bent section with flange type extensions on both sides provides a strong support for working platform with Cuplock steel battens. TOP |

| For use where distance between standards exceeds the span of scaffold boards Cuplock intermediate transoms Available in various lengths. TOP |

|

Similar to intermediate transoms, inside board transom is used for providing facility for a single inside board platform. TOP |

| The Return Transom is used at the end of a scaffold run where it meets another scaffold running at right angles to it. The U-shaped return section of the transom hooks over the ledger of the adjacent scaffold, closing off the gap between the two scaffold. TOP |

| The Ladder Access Transom is used to provide an opening in a bay allowing a ladder to pass through it. The L.A. Transom is attached to and spans between the ledgers in the bay. TOP |

|

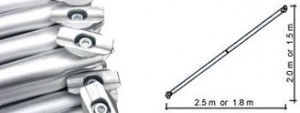

For diagonal bracing of scaffolding a range of longitudinal braces made with swivel forged blades at either ends to be fitted into cups of Cuplock standards are available.TOP |

|

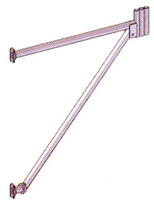

This item is used for providing support to decking or formwork at edges. This frame has ledger blades to be fitted into cups of Cuplock standards at one end and with provision for accepting jacks in three positions at the other end at 1.2 m, 1.25 m and 1.3 m from centerline of the standard.TOP |

|

It is fixed on the main vertical supporting beams and can avoid separate vertical for supports of slab form work.TOP |

|

Hop-up Brackets are designed in omega sections as well as in tubes sections for placing battens with provision of forged blades to be fitted with Cuplock standards by cup joint. Omega Hop-up brackets are available for single board, two board and 3 board allocations. TOP |

Socket Base And Universal Jack

|

Universal JackThe Screw Jack provides a method of jacking which can be used at either the top or bottom of a scaffold structure. It is used in conjunction with Forkheads, Socket Base and Drophead Adaptors.Socket BaseThe Socket Base is used in conjunction with the Universal jack and is drilled to allow for the insertion of a securing bolt if required. The dimensions are as mentioned.Loose SpigotMade out of 300 mm long square tube and with out and bolt spigots are used for connecting verticalsAdaptorThe Drophead Adaptor units provide for the easy conversion of Dropheads from the Waffle and Trough or Metriform Support Systems for use with Cuplock. TOP |